For a few years now, Hiab has been manufacturing bolt-on subframes to make it easier and faster for dealers and bodybuilders to turn a heavy-duty truck chassis into a dedicated crane or hooklift truck. Now, the company has launched a pair of modular truck body kits to add even more functionality.

"When customers buy a crane, they want it on the road as soon as possible, while bodybuilders want to serve as many customers as possible,” says Hiab’s Director of Heavy Loader Cranes & FrameWorks, Marcel Boxem. “Our new modular installation systems for truck bodies reduce installation time significantly.”

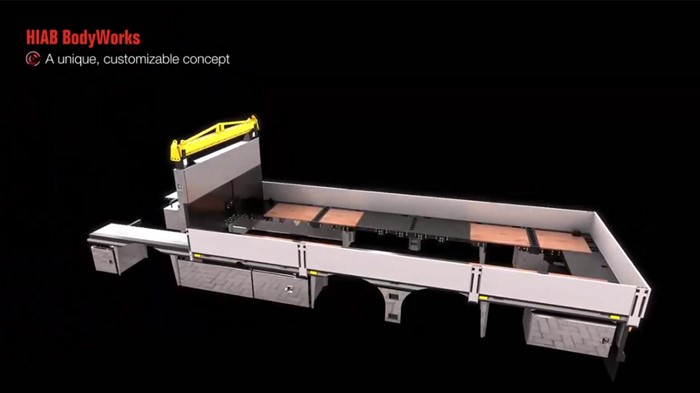

The new kits—called Hiab BodyWorks for trucks with heavy cranes and Hiab T-Body for T-series (T-009 to T-038) light cranes—add a flatbed behind the crane and pump area. Hiab suggests it can be used as a stake side bed, or for a water tank or dry van body, as examples.

BodyWorks

Being bolt-on systems, the BodyWorks and T-Body kits are easy to install quickly. There’s no welding, grinding, or painting required, nor any specialized skills. Moreover, it’s easy to remove and replace parts as needed by turning a few nuts and bolts.

Hiab uses robotic welding, laser cutting, and anti-corrosion paint dipping to form precise, long-lasting, lightweight parts for BodyWorks and T-Body kits. The main components are the headboards, wheel arch modules, and rear sections.

The company also includes side raves, cross members, lashing points, and floor panels of your choice. It offers three packages of options and accessories including toolboxes, mudguards, drop steps, working lights, and wide load signs.

Note that the T-Body is compatible with L2- and L3-length chassis. Its crane can be installed on any corner of the bed.

FrameWorks

Both the BodyWorks and T-Body require a truck that’s been equipped with a sturdy Hiab FrameWorks subframe. Introduced in late 2016, the platform comes with a crane, hydraulic pump, tanks, and auxiliary stabilizers.

FrameWorks is compatible with trucks from the likes of Volvo, Renault, Scania, and DAF. Like BodyWorks and T-Body, it’s bolt-on in nature, so installation is reversible and brief.

"With Hiab FrameWorks we reduced the installation times of frames for our heavy range cranes by 75%, and now we reduce the installation time needed for bodies by 75%,” says Boxem. “Using T-Body, a Hiab T-series light range crane can be installed in only four hours."

Faster installation means a cheaper installation, so this translates into money saved for end users, dealers, and bodybuilders. Hiab also offers installation services at its Meppel facility in the Netherlands. The company is part of Cargotec.

TruckLocator has a sizable selection of quality used crane trucks for sale.